Production introduction:

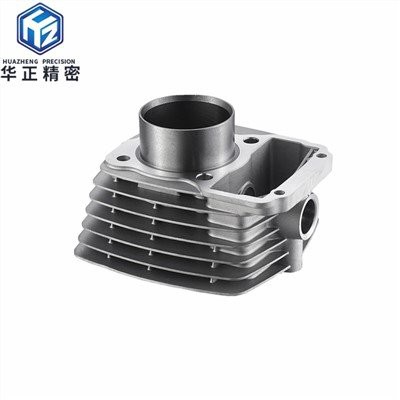

One of the key parts of aluminum die casting is the tooling for the parts to be produced, which is generally made of high quality steel and can be reused to produce aluminum parts. The accuracy of the mold determines whether the dimensions of the produced aluminum parts are accurate, whether the contours and textures are sharp, whether the surface is smooth enough, etc.

How are Aluminum Die Castings Made?

The die for die-casting aluminum alloy parts is usually composed of at least two parts because of the need to facilitate the removal of the casting. Whether the aluminum casting mold is simple or not is determined by the complexity of the aluminum alloy casting. Aluminum die casting mold design: divided into product splitting, runner design, slider, ejector, exhaust, slagging design, etc. At the beginning of die casting, two mold halves are clamped together by the casting machine. The hot liquid aluminum alloy is then injected into the mold cavity and rapidly solidifies. The removable half of the mold is then opened and the aluminum casting is ejected.

Advantages of Aluminum Die Casting:

It is possible to make metal parts with clear shapes and thin biscuits and deep cavities. Because the molten metal adheres to high fluidity under high pressure and high speed, it is possible to obtain metal parts that are more difficult to process than other processes. The unique appearance and light weight of die-cast aluminum parts are important advantages for freight logistics. The relative density of aluminum alloy profiles is significantly lower than that of pig iron and cast steel, but much higher in terms of compressive strength and corrosion resistance. Therefore, under the same load weight, it is possible to reduce the weight of the structure by using aluminum alloy die-casting.

FAQ

Q:How about your quality?

A:We have got ISO9001:2015 Certified.We will make the operation instruction once the sample is approved.We will 100% inspect the products before shipment.

Q: How soon can I get samples?

A: Depending on your specific project, it usually takes 10 to 20 days.

Q: Can my design be safe after sending it to you?

A: We can sign the NDA before you send it.

Contact:Cindy Zhu

Company:Shenzhen Huazheng Precision Technology Co., Ltd.

Tel:+86 13418453374

WeChat:+86 13418453374

Skype:CindyZhu Huazheng

Email:cindy@huazhengcnc.com

Address: 1st F East 4th Bldg, DaZhongGang Industrial Zone, Wanfeng, Shajing Town, Baoan Dist., Shenzhen, Guangdong Prov., China