Product introduction:

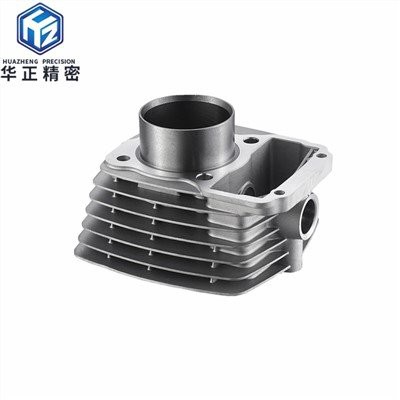

The Aluminum Die Casting Telecommunication Housing Parts are key components in the telecommunications industry. The parts are manufactured using the aluminum die-casting process, which involves pouring molten aluminum into a mold to obtain the desired shape and structure. The performance of these aluminum housing components is excellent. Firstly, aluminum die casting ensures a high level of precision and accuracy in the manufacturing process. This allows for a seamless design and a smooth surface finish, making the housing components more visually appealing. Second, aluminum is a lightweight material, making these components easy to handle, transport and install. In addition, aluminum has excellent thermal and electrical conductivity. This ensures efficient cooling and reliable connections, respectively. Plus, our products offer exceptional durability and strength. They can withstand harsh environmental conditions, including extreme temperatures, humidity and corrosion. This durability ensures protection of the delicate telecommunications equipment inside. Finally, we have excellent performance in precision, light weight, durability and conductivity. These qualities make them ideal for the telecommunications industry, ensuring the smooth operation of various communication systems.

Product Feature

The Aluminum Die Casting Telecommunication Housing Parts are widely used in the telecommunications industry due to their unique features and performance. The parts are manufactured using a die-casting process that involves injecting molten aluminum into a mold to create the desired shape. First and foremost, we have decent strength and durability. Using aluminum as a material ensures that these components can withstand high levels of stress and pressure. Additionally, they are corrosion resistant and can withstand harsh weather conditions. Second, the parts are versatile in design and can be adapted to a wide variety of telecommunication equipment. The aluminum die casting process can create complex shapes and intricate designs, making it ideal for the production of telecommunications enclosure parts. Third, the lightweight nature of our products makes them easy to handle and install. This feature makes them cost-effective and ideal for mass production. Finally, its unique properties make it indispensable in the industry. Their strength, versatility and lightness are key factors that make them highly sought after by telecommunications companies.

Product specification:

Name | 1.Aluminum die casting telecommunication Housing Parts |

Material | ADC12, A380, AlSi9Cu, ADC10 |

Dimension | Mini 80*80 mm, Max800*800 mm |

Technology | High Pressure Die Casting, CNC, CMM Measure, Painting, X-Ray Detection |

Processing | 1, Sign Drawing (General clients provide the drawing or samples) |

Application | Automobile 42%, Furniture 21%, Industry 18%, Lighting 15%, Other 4% |

FAQ

Q1: When can I get the price?

A1.We usually quote within 48 hours after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q2. How about your lead time?

A2: Die casting mould will take 30 after receiving your advance payment. For Mass production,

The specific delivery time depends on the items and the quantity of your order.

Q3: Can you produce according to the samples?

A3:Yes, we can produce by your samples or technical drawings. We can build drawings for you after we get your samples too.

Q4. Do you test all your goods before delivery?

A4:Yes, we have 100% test before delivery

Contact:Cindy Zhu

Company:Shenzhen Huazheng Precision Technology Co., Ltd.

Tel:+86 13418453374

WeChat:+86 13418453374

Skype:CindyZhu Huazheng

Email:cindy@huazhengcnc.com

Address: 1st F East 4th Bldg, DaZhongGang Industrial Zone, Wanfeng, Shajing Town, Baoan Dist., Shenzhen, Guangdong Prov., China